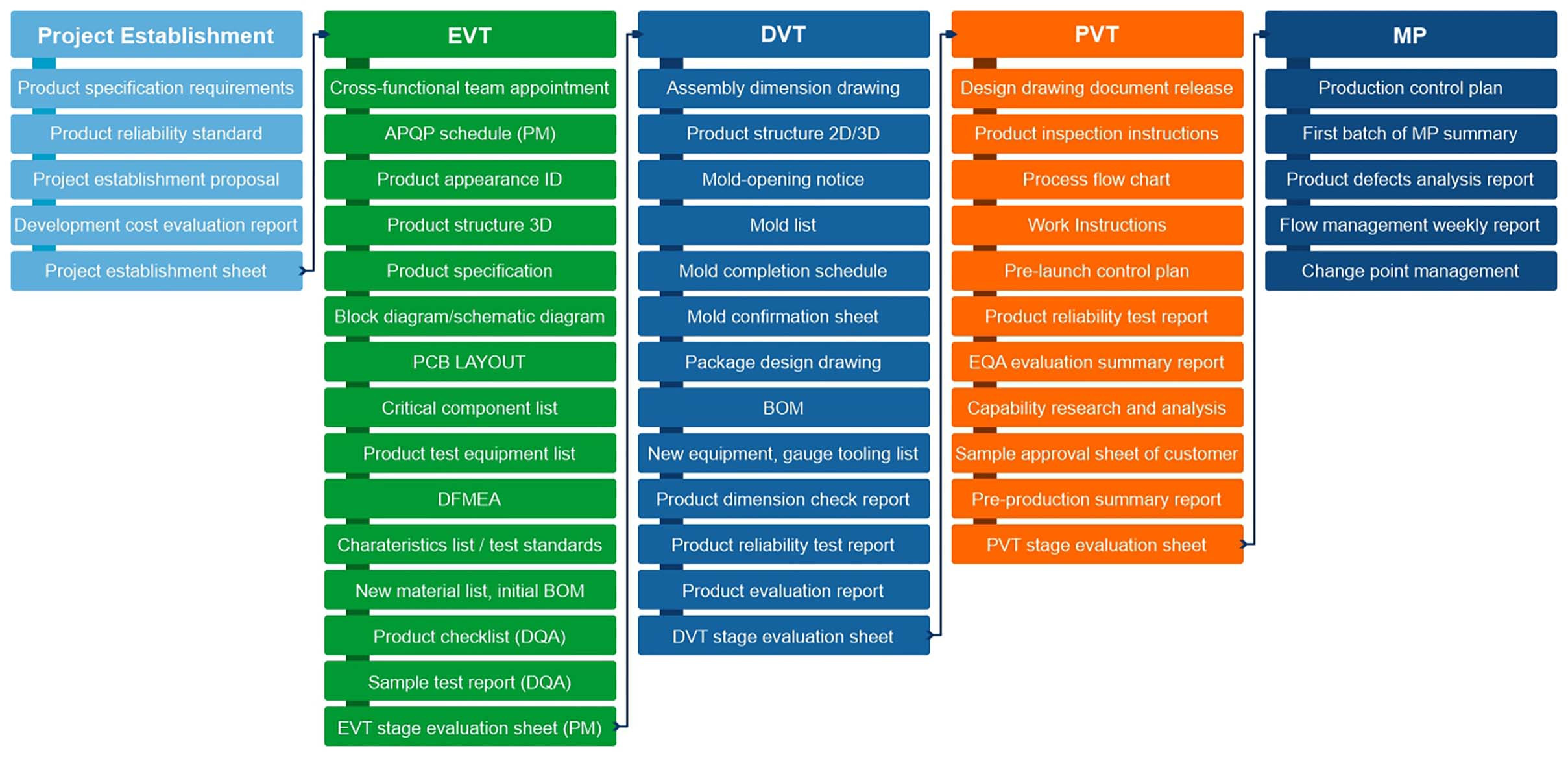

SUMER has years of experience in the OEM parts supply field and provides its services to customers in line with a comprehensive project classification. For OEM projects, SUMER starts with regular meetings with car factory engineering and design sector people to finalize the requirements and design of the product, mutually agree on them, document them, and freeze them. When the project is well-defined and all parties involved have a perfect understanding of it, SUMER issues a Product Design Specification (PDS) that covers all aspects of the project to document its understanding of the project. SUMER then proposes the price, contract terms, and timetable for R&D and production stages to the customer. Once the contract is signed, the team categorizes the project timetable based on its nature. SUMER follows the steps illustrated in the chart below as a sample for developing electronic parts.

To achieve excellence in cost, risk management, and technology integration, we depend on a successful and sustainable network of suppliers to develop state-of-the-art products and services. In addition, SUMER sets up production lines and test facilities for mass production of the developed parts, which is done in parallel with the parts development and realization process.

The increasing number of turn-key projects has cemented SUMER’s status as a center of excellence.